The cost of launching a product without testing it can have huge disadvantages.

It increases your production cost because you have to repeat several processes; it could also lead to low-quality products from inaccurate testing processes, extend your production period, among other consequences.

Fortunately, this is where design simulation software comes in. It provides a detailed analysis of a product to examine its functionality before a launch.

In this article, we will discuss the top three benefits of design simulation software for design engineers to help you make the most of the benefits it comes with.

Let’s get started.

What is design simulation software?

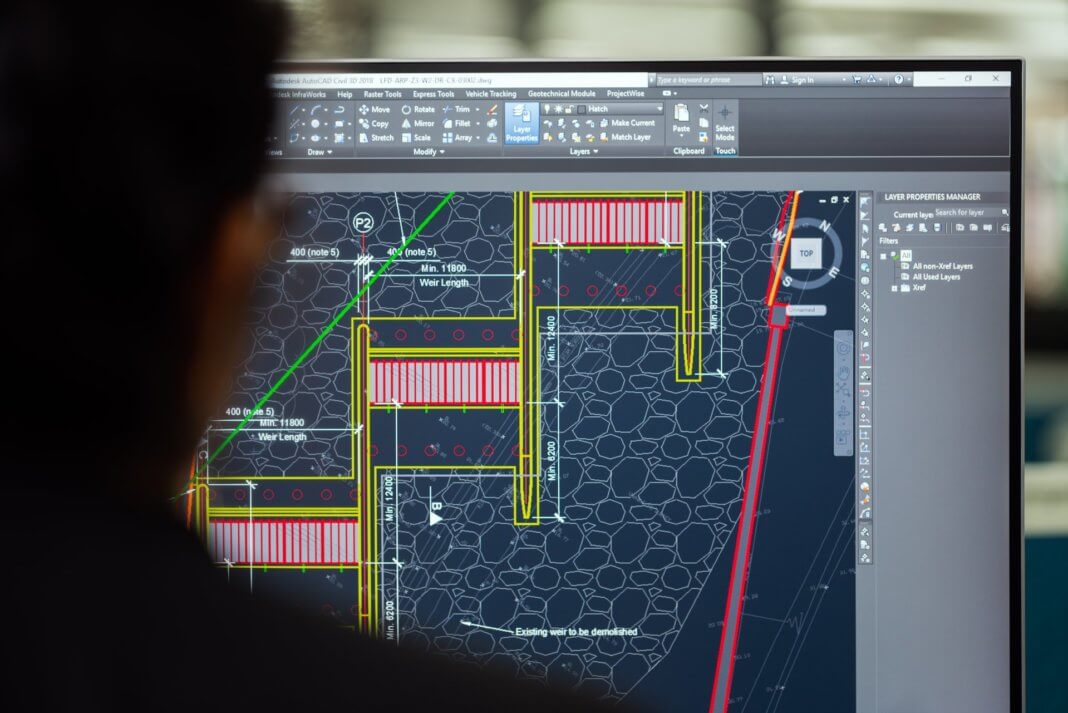

Design simulation software is used by engineers, manufacturers, and architects to examine how functional a product is before its launch. It enables them to figure out if a product meets their expectations based on their requirements, which could be its features, strength, speed, or lifespan.

It’s necessary for a product to be digital in order to run through a design engineering simulation software because it is done virtually.

Design simulation involves creating a virtual environment to examine how a product will perform in real-life. In the virtual environment, all possible scenarios would be explored to identify how a product would perform when faced with such scenarios in reality.

This could involve placing objects, introducing electric current, increasing sunlight effect, and placing other natural phenomena in the picture to see how a product would react or cope with them.

With design simulation software, engineers and designers can identify the inadequacies of a product to make improvements and deliver the best results.

You can adopt a design simulation software to run multiple tests on different products; from discovering how a metal door would work to how an automobile will work on the road.

Although specific products require different simulators depending on the type of product it is, the end goal is always the same —evaluating a product’s performance in use.

However, design simulation products are mostly used for prototypes or design in their conceptual stages; when used on manufactured products, they do not deliver the unique reason for simulation software- which is identifying the possible shortcomings of a product before production or launch.

Top 3 benefits of a design simulation software

Engineers, manufacturers, and designers use design simulation software to test a product in its actual usage, enabling them to identify errors and manufacture quality products that meet their expectations.

However, there’s more to what design simulation software can do for design engineers. Let’s examine the most prominent benefits below:

-

It saves the cost of production

Before the existence of design simulation software, design engineers, architects and manufacturers created physical prototypes to evaluate if a product would perform well in real-life usage.

They analyze the errors they identify from the first prototype; then, they create a new prototype to implement the changes they make. They keep creating prototypes to implement the changes they make until a prototype meets all their requirements.

Then, they create the final product and launch.

The problem with this process is that it isn’t only time-consuming or rigorous; it is also expensive. For example, to get the perfect design for a car, the design engineer would have to go through several physical prototype testing, leading to multiple use of resources which are associated with extra cost.

However, using a design simulation software requires virtual and not physical testing, which lets you skip the physical prototyping and save big on your design process.

Using a design simulation software doesn’t only create a virtual representation of your product; it also provides accurate data you may not acquire with a physical prototype.

The perk of acquiring accurate data-driven feedback on your product is that it reduces the chances of running a test repeatedly because you can use the data you have to make maximum improvement. This may enable you to create a perfect design after the first testing.

With this, you can minimize design costs because you won’t have to go through various testing processes and buy new resources for every stage of the testing process.

You will also see faster results with your designs because the design simulation software shortens the design process by reducing the number of times you test a prototype.

-

It prevents physical damages

Using a design simulation software prevents the damages that may occur when testing a product. This is because all tests are run virtually, so any damage that may occur with a product will happen virtually and not physically.

So, testing a product with design simulation software will only show the possible damages virtually, which doesn’t cause any physical damage to the original product. This helps to prevent the financial losses associated with the physical damage of a product because the actual product is non-existent yet.

For example, when testing a motorcycle with digital simulation software, the motorcycle only exists virtually, so if an accident occurs based on a passing pedestrian or an overhead bridge, all of these damages occur virtually and not in a real-life scenario.

Therefore, rather than experience the financial loss that comes with physically damaged products, buildings, or death, design engineers can avoid these occurrences when they view the possible damages virtually.

Designers also benefit from virtual representations of the potential damage a product can cause by fixing them before they launch a product, which helps them mitigate future damages after a launch.

-

It enables you to get the most from your product

Software design simulation enables design engineers to design and manufacture products that are widely accepted by consumers.

The accurate data design simulation offer lets you make the best product improvements to manufacture quality products your users will find valuable. Because you know your products are designed to meet your users’ needs, you have the confidence to state prices that bring more profits.

In addition, working with a design simulation software means you will be able to experiment with a prototype before you manufacture it. This lets you conduct experiments in different scenarios to identify new market opportunities.

You can discover other scenarios where your product can be used. This helps you to expand your market and get the most from your product by exploring different opportunities with the design simulation software.

Apart from this, using it allows you to design a product that meets and exceeds your customers’ expectations, putting your product in high demand and helping you sell your product faster.

Also, because using it reduces your development cycle, you can produce designs faster and boost your users’ satisfaction, which helps you to sell more, faster.

Benefits of using nTopology simulation software

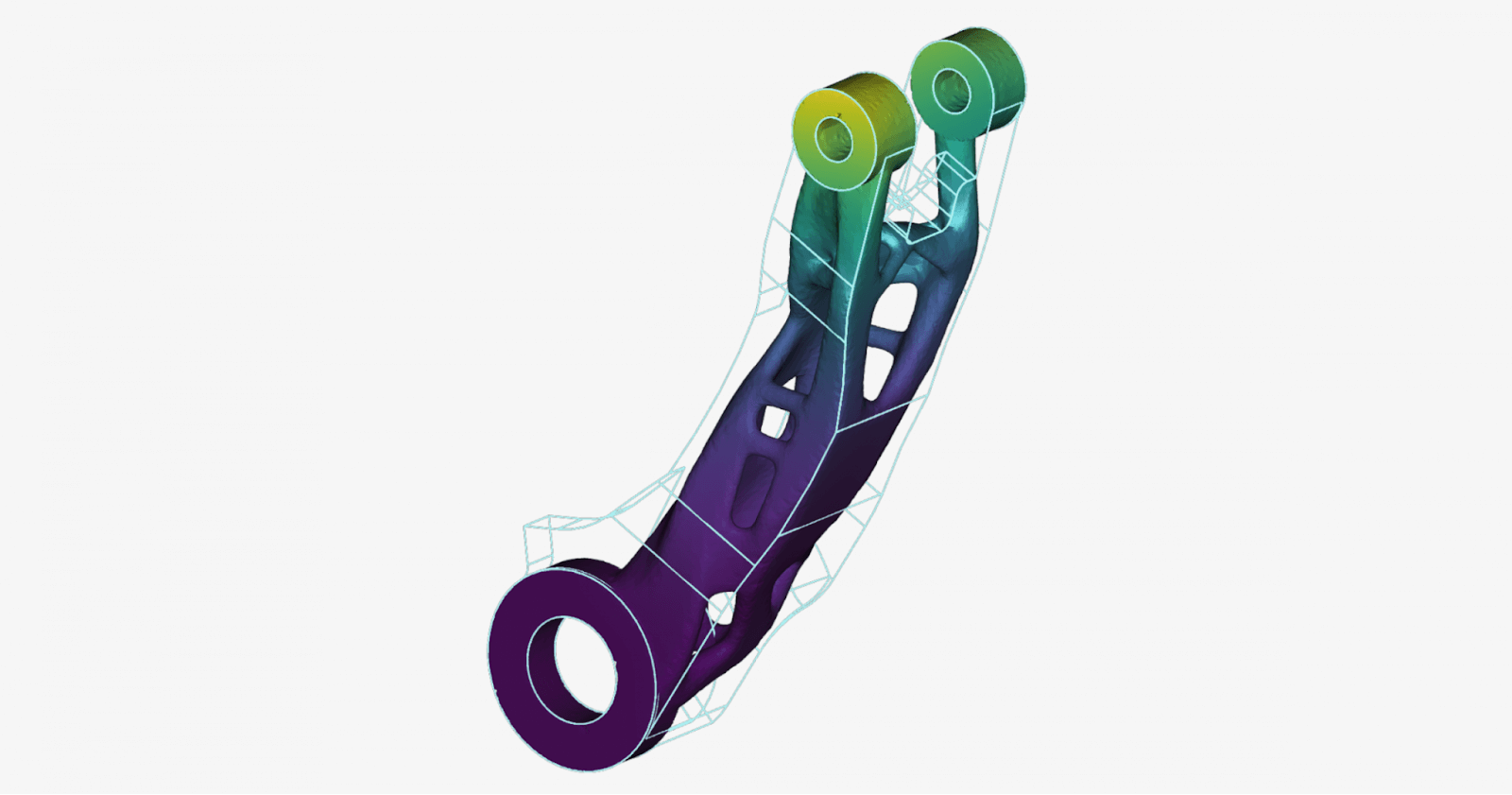

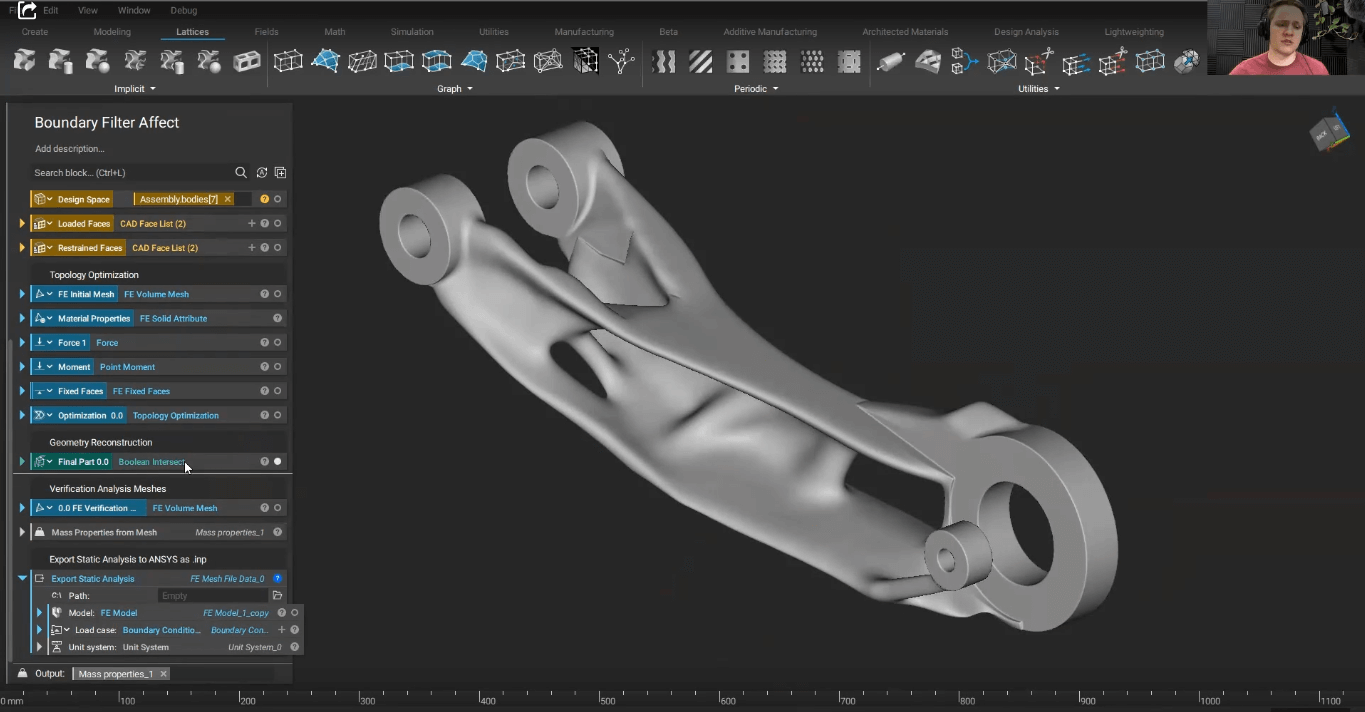

When using simulation software to design your product, it’s best to adopt an effective design simulation software like nTopology to get the best results.

nTopology is an engineering simulation software that helps you make the best design evaluation to create excellent designs.

It is the latest simulation platform for design and engineering as it is enabled with an unbreakable modeling technology that design engineers, manufacturers, and analysts can use to create excellent designs.

With nTopology, you can accelerate your design process. This allows you to test different variations of your product faster, deliver better results, and generate unique, high-performance parts.

Below are the top perks of using the nTopology design simulation software.

-

It enhances your simulation workflow

nTopology design simulation software streamlines your 3D design data connectivity, which improves your software stack. It lets you pre-examine your FEA models before you can transport your meshes to your CAE suite for a comprehensive attestation.

With the nTopology design simulation software, you can improve your Multidisciplinary Design Optimization (MDO) stack with powerful integrations.

-

It allows you enjoy built-in finite element analysis tools

nTopology design simulation software allows you to combine design generation with design analysis to maximize your time and produce top-quality designs.

It offers built-in mechanical and thermal finite analysis tools that let you develop multi-physics control systems in your workflow to test how each part of your product is performing.

-

It facilitates reusable engineering simulation processes

nTopology design simulation software allows you to transport your engineering simulation from the middle stages to the latest stages of your process to the beginning. This helps you to identify errors at the initial stage of the design process, saving time and resources.

With this, you can make changes and edits at the beginning of your designs, to improve your prototypes and create excellent designs.

Conclusion

Design simulation software is a must-have for designers, engineers, and manufacturers who want to produce excellent products through effective prototype testing. In this article, we discussed the three core benefits of using design simulation software.

First, design emulation software helps designers, engineers, and manufacturers cut down on production costs. Second, it also helps them to avoid physical damage to their products because testing is operated digitally, and thirdly, it enables designers to maximize their designs by supplying them with accurate data and reducing the production downtime.

Using a design simulation software like nTopology can help designers produce high-performance products because it is equipped with enhanced modeling technology features that produce the best results.

Also Read: 5 Quick Design Tools for Marketing Pros and Non-Designers!