If you’ll search top trending technologies on Google, I can bet you will come across the term 3D printing alongside other racehorses like Deep Learning Algorithms, Advanced Biometrics, IoT-based devices, Blockchain, AR VR & others. Now it seems everyone from Amazon to the White House is talking about it! But what exactly is 3D Printing, how 3D Printing works, & what are the applications of 3D Printing?

Well, when we talk about 3D printing it seems we are already living 20 years ahead from now. Imagine a machine that has the ability to create any things, from toys, ceramic cups, vases, to metallic machine parts, and even chocolate cakes. You imagine and 3D printers can create it. And yes, one day it might even create human body parts!

You read it right, & if you have ever come across any such devices then it wouldn’t take so hard to digest the above facts. The concept of 3D printing is now literally challenging the traditional hard ways of producing things with just a bunch of advanced printers & some raw materials.

So, what is 3D printing? How can it create any imaginable thing?

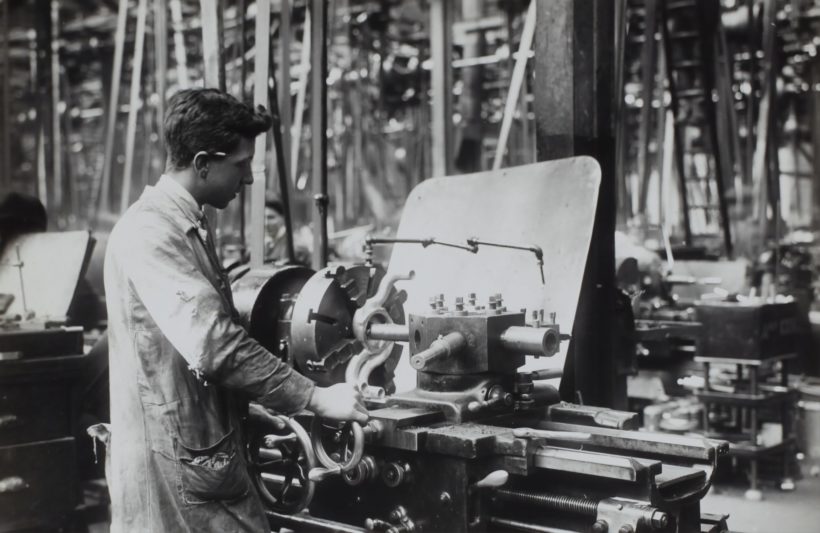

Wait before understanding 3D printing, let’s first go into flashback and try to understand the roots behind this amazing technology.

What Is The History Of 3D Printing!

Though many will assume that this remarkable technology is relatively new and won’t have any remarkable history to hoot for- but you’re wrong!

The early history of 3D printing can be traced back to the 1980s, all thanks to the efforts of Dr. Kodama. It was believed that he was the first one to file the patent for 3D printing, which was then called Rapid Prototyping or RP technologies.

The irony of this story is that though Dr. Kodama from Japan was the first to conceive this technology and file the patent, unfortunately, he failed to file the full specifications before the 1-year deadline. It was ironic & disastrous to some extent because Dr. Kodama was a patent lawyer!

If you will go by the papers, then it was the year 1986 when the first patent for stereolithography apparatus (SLA) was issued. And it is believed to be the first origin of 3D printing. This patent was issued to Charles Hull, who invented SLA in 1983. Later, he also co-founded 3D System Corporation – one of the most recognized, reputed & largest organizations operating in the 3D printing domain currently.

The 1st commercial RP system called SLA-1 was introduced to the market in 1987 after rigorous testing. In the same year, Carl Deckard filed a patent in the US for Selective Laser Sintering (SLS) RP process. Its patent was issued in 1989 and was later licensed to DTM Inc, afterward, it was acquired by 3D Systems.

In 1989, Scott Crump (co-founder of Stratasys Inc.) also filed a patent for Fused deposition Modeling (FDM) and its patent was issued in 1992 to Stratasys. The company still holds this proprietary technology along with several other RepRap models that are currently being used.

In 1989, Hans Langer was the one who started the race in Europe for 3D printing, He was the first one to conceptualize EOS GmbH in Germany. Its focus was heavily on the laser sintering (SL) process. Even today, these EOS systems are known for their quality results for industrial production & prototyping all over the world.

During these years, other 3D printing technologies & 3D printing processes also emerged. Some of the popular ones being Ballistic Particle Manufacturing (BPM), Solid Ground Curing (SGC), Laminated Object Manufacturing (LMO), 3-Dimensional Printing (3DP), and others.

Throughout the 1990s & early 2000s, various similar concepts and processes of 3D printing emerged, but a majority of them were revolving around industrial applications or for prototyping applications. But alongside these, some research was being carried out for more advanced technologies with the aim of casting, tooling, and direct manufacturing applications. This led to the birth of Rapid Casting, Rapid Tooling (RT) & Rapid Manufacturing (RM).

During this time, one who has experienced the evolution of this technology can easily tell you that 2 distinct diversification with 2 specific areas were going on.

One was more towards high-end 3D printing which was expensive, complex, and highly engineered. Even today, it is still growing but the impact can only be seen in the aerospace, health, jewelry, and automobile sector. On the other hand, some manufacturers started developing “concept modelers”. Specifically, these are the 3D printers whose function and the concept have been regularly improved. It was literally developed for office use and was user-friendly and very cost-efficient.

Still, this was the calm before the actual storm!

After this, a price war emerged for the lower end market of 3D printers. It led to significant improvements in accuracy, output, speed & materials with less cost. By the end of 2007, anyone could have acquired a 3D printer for $10,000. But still, it didn’t garner popularity.

After this, getting a 3D printer under $5000 became the holy mantra for all the players. When you look back from now, it will be cleared that actually, it was the year 2007 that was the turning point in the 3D printing industry. Because it was the year when all the RepRap models started gaining popularity. In this year only, the open-source 3D printing movement gained much-needed visibility across the world.

In Jan 2009, the first commercial 3D printers were made available & it was based on the RepRap concept. In 2012, an alternative 3D printing concept was introduced via a crowdfunding website called Kickstarter. This concept soon became a huge success. In the following years, 3D printing evolved significantly with much cheaper rates.

Today, some even referred to this evolution as the 3rd or 4th Industrial Revolution – all thanks to its capabilities & the impact it has created in the industrial sector. Now, what’s more interesting is to see the upcoming years for all the remarkable breakthroughs that still need to get unfolded before us.

What Is 3D Printing Technology?

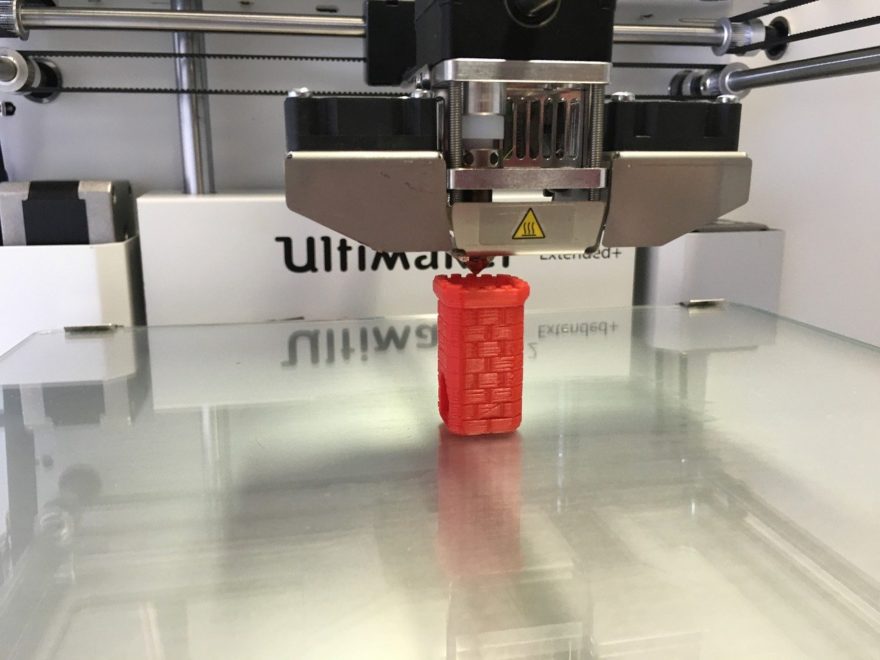

In very simple terms, 3D printing is a concept wherein a machine or printers print a final object using various 3D software programs and different materials.

To make this concept more simpler, take the example of a regular printer, When you print any document from your printer, all the letters, images or characters don’t just come with magic, but at the microscopic level, these are sprayed making them sit tightly on the surface of the paper.

Theoretically, if you print the same thing on the same paper over and over again, then eventually ink will start building up leading to a certain number of layers that will be enough to create a 3D solid model. The idea of a modern 3D printing comes from this basic fact of forming tiny layers on top of each to create an actual object. Just the difference was the use of materials and the software.

Currently, various 3D printing software like Tinkercad, Blender, FreeCAD, OpenSCAD & others are available for creating digital models. Once it is created using any type of 3D printers, you can print the model using different types of materials like plastics, metals, ceramics, sands and so on.

Aggressive researches are being carried out in 3D printing for using edible materials for creating several types of food & chocolates.

Also Read: 18 Best 3D Printing Tools- Boost Your Productivity & Work Efficiently!

How Does A 3D Printer Work?

In general terms, you can imagine the process of 3D printing as making bread. Wherein, you are not just baking it, but in this case, you are baking each piece of bread and then putting each layer on top of the previous one to create the whole structure. Once done, you are gluing them together into a whole loaf.

3D printing does exactly this. It converts the entire object into thousands of small pieces and then puts together each piece on top of each other to create the final object. In many cases, these layers can be very complex, meaning it can be used for creating a bike saddle, frame or breaks or hinges, or wheel which all will be ready to assemble upon completion.

But when talking more scientifically, I will only say that there are different types of 3D printers that are being used for different purposes. One of the major limitations of this technology is that ‘no one solution fits all’.

For instance, some printers can use polymer resins & use light or laser for solidifying it on ultra-thin layers, while some printers use powdered materials like plastic, nylon, metal, or ceramic and use light or any heat source to melt or sintered or to fuse it as per the defined shape.

Another process of 3D printing is spraying fine droplets just like any 2D inkjet printer but with different types of materials that are better to bind or fix. A majority of the 3D printers that are currently being used are based on the most common process for deposition. It requires plastic in the filament forms which is then extruded to form layers for creating the final object.

What Are The Limitations Of 3D Printing?

As said earlier, the major limitation of 3D printing is that it is not necessary that one type of printer will be a good fit for all your needs. Another is that you can’t use it as a plug and play option, that many of us prefer these days. Before printing any model, there are various processes that you have to complete.

Apart from just creating the model in software, you are also required to prepare the file and then its conversion. It is a complicated and time-consuming process. Before printing, you are also required to check for finishing operations such as support removal, sanding, paint, lacquer, and others. All these require time, patience, and most importantly a skilled set of hands.

What Are The Applications Of 3D Printing?

As of now, it is clear that the foundation of 3D printing is based on the principles of Rapid Prototyping with the more quick and simple processes that have the capabilities to create several iterations of any product at fast speed and efficiency. Current printers save both money and time for any development process.

All the developments & improvements in the processes and materials for current 3D printers have led to some of the most advanced, accurate & cost-efficient versions of 3D printers. These are heavily being used for tooling and casting applications across almost all industries.

All the improvements are still being made to facilitate the uptake. To learn about all the applications of 3D printing, we have to break down its market that is currently using it heavily. These are as follows:

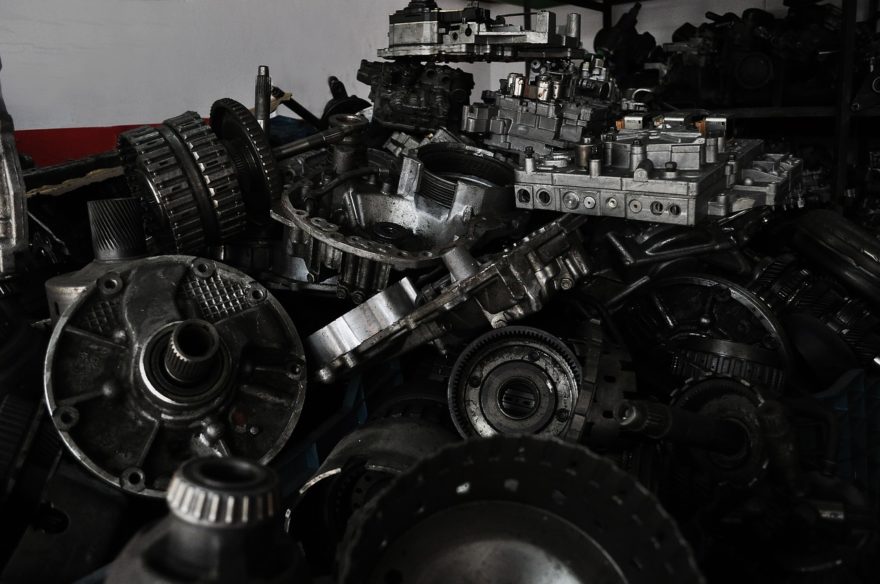

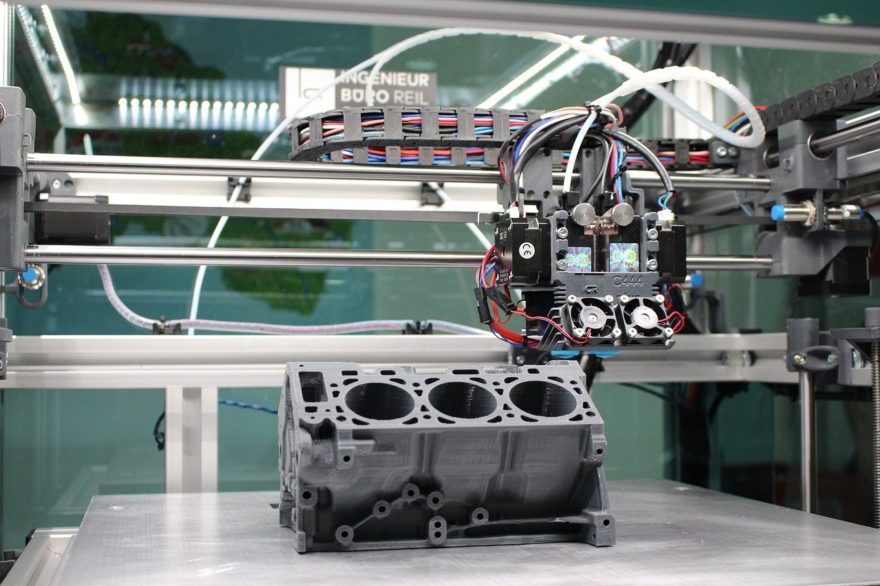

#1. Automotive

It is one of the early adopters of rapid prototyping (RP) technologies. Some even argue that 3D printers were first used in the automotive sector. Certain top automotive companies especially the F1 or companies in motorsports have taken the inspiration from aerospace to utilize the 3D printers.

They were one of the first industries that are still using this technology, but now they have also started to adapt and develop their manufacturing processes to cash on all the benefits of improved results & materials for automotive parts.

Some companies in the automotive industry are also eyeing all the potentials of 3D printing to enhance their sales results in terms of production for spare parts or parts involved in replacement as per the demand. It helps them to avoid storing large amounts of these parts, saving up the loss of inventories, space & money.

#2. Health

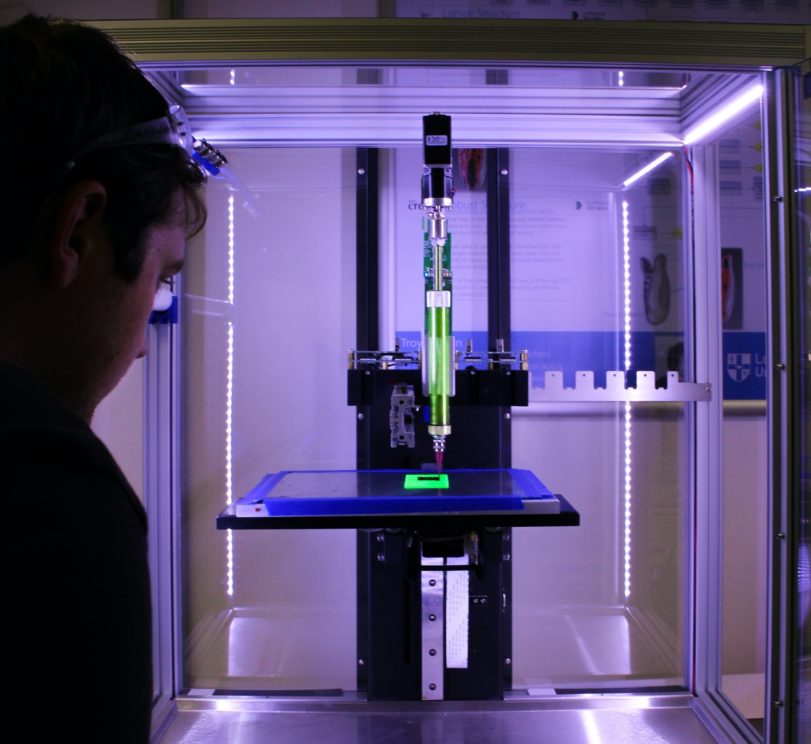

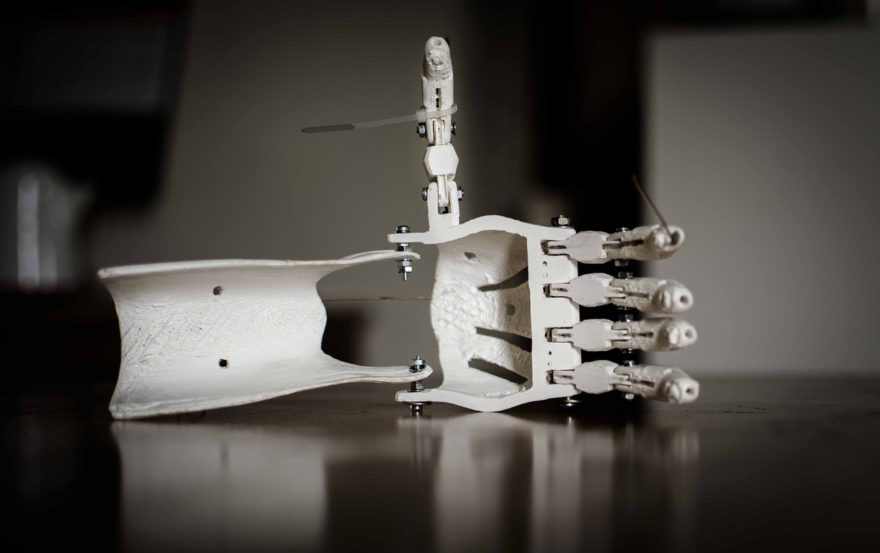

It is also believed to be the earliest adopters of 3D printing. The medical sector is also considered as a huge market for 3D printers because of certain abilities of these devices such as customization & personalization. 3D printers can literally improve the lives of myriads of individuals by developing materials as per the requirement and of medical grads standards.

In the health sector, 3D printing is used for a wide spectrum of applications. For instance, one of the most popular uses is for making prototypes to support the development of any new products in the medical or dental industries. It is also being used for dental crowns to make patterns for the downstream metal casting. Not only this but can also be utilized to make all the tools on which plastics can be vacuumed. It is done for creating dental aligners.

Moving over dental applications, 3D printers have become popular for manufacturing both stock items or bespoke patient-specific products. Here stock items can be hip or knee implants, and bespoke products related to patients can be personalized prosthetics, hearing aids, orthotic insoles, and personalized implants for patients having certain conditions like cancer, osteoarthritis, osteoporosis, and so on.

You can even count on these technologies for individuals who have faced an accident or trauma victims. Currently, one of the recent developments like 3D printed surgical guides has become more popular. It assists surgeons in their work and helps patients to recover.

Research in 3D printing is going on for certain applications like creating a skin, tissue, bone, pharmaceuticals, and human organs as well! However, experts believe that still, almost a decade of time is required for making this a reality.

#3. Aerospace

Just like the other 2 listed above, aerospace was also one of the early adopters of 3D printers. They adopted this technology when it was in its earliest stage of development and prototyping. The companies from these sectors were the ones who were responsible for pushing the boundaries of 3D printers to the limits for manufacturing top-quality applications and with precision.

Because of the criticality of the aerospace industry, all the research and development happening was strenuous and demanding. All the standards were critical and all the 3D printing systems were tested to the limits along with its final products. Because of these things, a number of significant developments were seen in the processes and the materials utilized for 3D printing in the aerospace industry. Till the time, apart from all the critical parts, some non-critical 3D printed parts were already being used in flying aircraft.

Some of the big names that used 3D printers were Airbus / EADS, Boeing, GE / Morris Technologies, Rolls-Royce, & BAE. In terms of progress, many of these choose a more realistic approach while some often get bullish when it comes to future development.

#4. Jewelry

Since the very beginning, the manufacturing and design processes in the jewelry industry have always had the demand for highly skilled individuals having a top level of expertise and knowledge. It includes mold-making, electroplating, fabrication, casting, stone-cutting, polishing, forging, silver/goldsmithing, and engraving. All these skills have evolved significantly over the years and require years of technical knowledge and experience. To give you an example, consider investment casting whose origin over 4000 years.

In this industry, the concept of 3D printing has been nothing less than disruptive. It has attracted almost everyone with all its potential and applications. People are more keen to see how 3D printing can be used and contribute to the jewelry industry over the next few years.

To just give you a gist about the use of 3D printers in the jewelry sector, it gives freedom to the experts for creating digital designs over 3D CAS and can directly print the jewelry by eliminating all the traditional and hectic processes. Definitely, this technology in this sector is having a huge impact and in the near future, it will create a greater impact benefiting everyone in this industry.

#5. Architecture

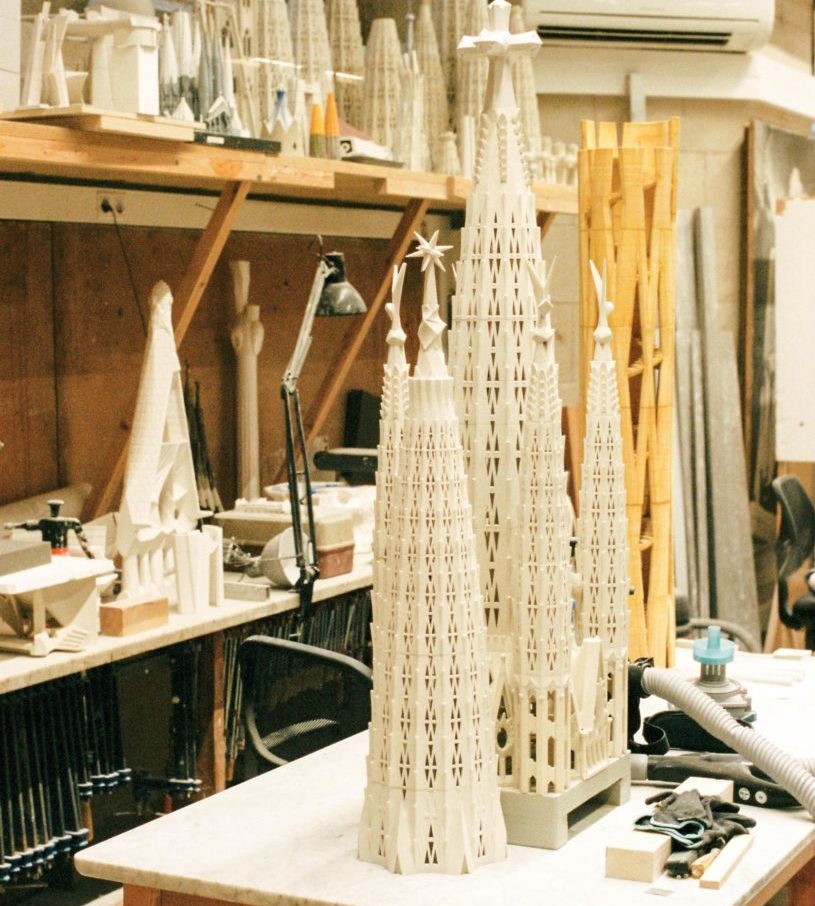

For years, architects have been using 3D printers for creating architectural models to demonstrate accurate information and the true vision behind any project. With 3D printers, they can achieve an easy, fast, and economically viable way of developing a detailed model directly from 3D printing software like 3D CAD, BIM, or any other popular names among architects.

Some renowned and successful architect firms and companies have made 3D printers important & critical for their workflow. It is mainly done to increase efficiency, innovation, and to improve communication.

In the last few years, some visionary architects have come up with the idea of using 3D printers as a direct construction method. Though it is still on paper, heavy research is currently going on. Some notable names that are in this race include Contour Crafting, Universe Architecture, Loughborough University, & others.

#6. Art

You can find hundreds of ways through which artists, designers & sculptors have engaged with 3D printers to explore new forms of design or to create a model that was previously believed to be impossible. This is one of the busiest domains when it comes to the application of 3D printers. They are constantly finding some or other new ways of utilizing 3D printers for completely different results.

As of now, there are several notable artists who have gained immense popularity by using technologies like 3D printing, 3D modeling & 3D scanning. Some of these names are Dizingof, Pia Hinze, Joshua Harker, Lionel Dean, Jessica Rosenkrantz & many others.

The use of 3D scanning concepts along with 3D printing has led to a completely new dimension in the world of art. However, today’s students & artists are utilizing it more for reproducing or replicating the work of masters. These include creating the exact replicas of any ancient sculptures for a close study. Without this technology, this would have never been possible.

#7. Fashion

It is the industry that is known for experimenting and outrageous trends. Since the time, the process and the materials of 3D printing have been evolved and improved, this industry is racing like never before.

Already, fashionistas are experimenting with 3D printed accessories along with bags, shoes, hats & even headpieces. All these 3D printed products have also been part of several catwalks. Just like the architecture domain, some visionary fashion designers are hooting for utilizing 3D printers for haute couture capes, dresses, underwear, and even full-length gowns. All of these have already debuted at numerous fashion events across all over the world.

Among all, Iris V Herpen definitely deserves an honorable mention for this initiative. She has been successful in creating a number of collections that have been walked by top models in Milan & Paris. All these collections were based on 3D printing. Since then, many designers & enthusiasts started following in her footsteps creating the entire new concepts & designs in the fashion world.

#8. Food

This industry is one of the latest adopters of 3D Printers, and in many cases, it is still experimenting with the concept. Creating food with 3D printers are now becoming one of the emerging applications that make people excited.

Truly, if everything goes correctly, then 3D printers literally have a lot of potential in the mainstream food industry. It will become a revolutionary new way of preparing and presenting food for all the restaurants from all over the world.

All the initial experiments in the food industry happened on chocolates and sugar, and the recent developments made can now be seen hitting the market. Apart from these, other experiments included meat (at the cellular or protein level). Recently, the news of experiments on Pasta also came as a part of 3D printing.

In the coming years, 3D printers are considered as a method for preparing a complete dish or food by balancing all the nutrients in a healthy and detailed way.

What We Can Conclude From 3D Printing?

Here we are- wrapping up the entire story of a completely new technology that has already or set to revolutionize the lives of many. Some might consider 3D printing as a relatively new technology when compared to other trendsetters, but it has a long root full of competition, price wars & innovation.

Also, many may find its working principle simple as any inkjet printer but when it comes to the real 3D printers, it is way more complicated. It all varies as per the various types of 3D printers.

Just like any coin having 2 sides, 3D printing has its limitations as well along with all the benefits & applications. It might be revolutionary for many across various domains, but the fact is that it is still in its early phase with lots of on-going developments. This really makes the upcoming years interesting.

Lastly, coming back to its application, I have only mentioned some of the popular ones who are heavily using 3D printing, but in reality, it is being used by many others. Leave the industry, today, it is also being used at an individual level, where people can just Google & buy it for a fraction of the cost since the time of its initial commercial launch.

So I hope, now all your questions regarding 3D printers are cleared, & if still anything left, feel free to comment in the below section so that we can try to cover in our upcoming articles.

Also Read: 18 Best 3D Printing Tools- Boost Your Productivity & Work Efficiently!